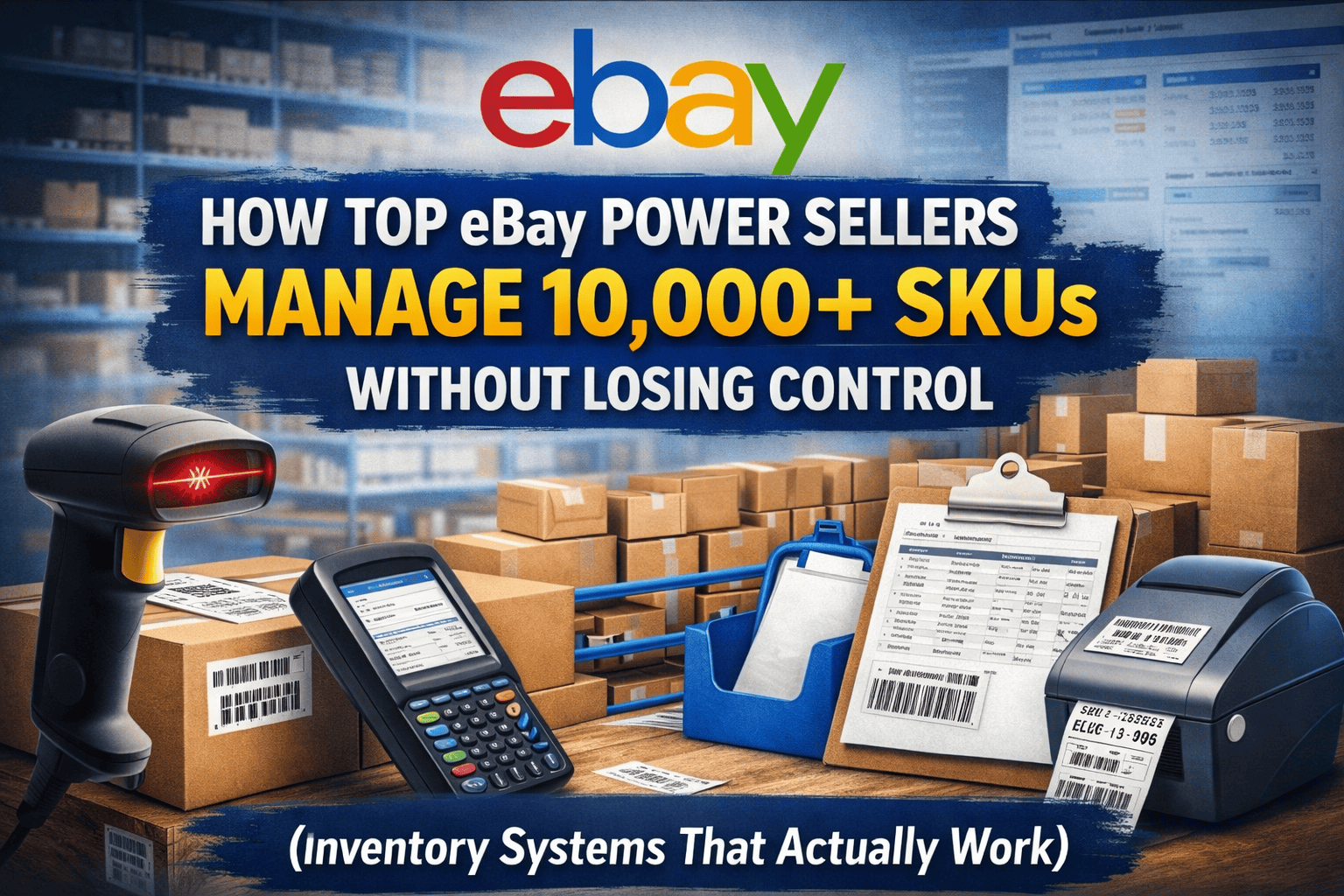

How Top eBay Power Sellers Manage 10,000+ SKUs Without Losing Control (Inventory Systems That Actually Work)

February 10, 2026

eBay Inventory Management for 10,000+ SKUs: Systems Top Power Sellers Actually Use

Managing a few hundred items on eBay is challenging. Managing 10,000+ SKUs is an entirely different business.

At this level, you are no longer “just selling online.” You are running a logistics operation, a data system, and a supply chain - whether you realize it or not.

The difference between sellers who scale successfully and those who collapse under volume usually comes down to one thing:

Inventory systems.

In this guide, I’ll explain how top eBay power sellers manage massive inventories without constant overselling, lost items, refunds, and account defects. This is how professionals build inventory operations that actually work.

Why Inventory Becomes the Biggest Threat at Scale on eBay

As your catalog grows, inventory stops being a simple storage problem. It becomes the central risk in your business.

One incorrect quantity can lead to overselling, order cancellations, negative feedback, and rising defect rates. One misplaced item can cause refunds, shipping delays, and customer disputes. Multiply that by thousands of SKUs, and small errors quickly turn into serious financial damage.

High-volume sellers understand that inventory is not just about shelves and boxes. It represents working capital. Every unit sitting in your warehouse is money invested in your business. If you lose control of that inventory, you lose control of your cash flow.

That is why elite sellers treat inventory management as a financial system, not a warehouse task.

Why Professionals Think in Data Before Physical Products

New sellers usually organize their business around physical space. They think in terms of racks, bins, and boxes. Professional sellers think in terms of data.

Every item in a serious eBay operation must exist accurately in three places at all times: in your physical location, in your inventory software, and in your live eBay listing. If any of those three become disconnected, problems start immediately.

When inventory data leads the operation, everything becomes easier. Picking is faster. Updates are automatic. Overselling is minimized. Staff can be trained quickly. Decisions become measurable.

At scale, data is your real warehouse.

Centralized Inventory Systems Are Non-Negotiable

No high-volume seller relies on eBay alone for inventory tracking. That approach fails as soon as volume increases.

Professional sellers use centralized inventory platforms that act as a master database for their entire business. Every SKU, variation, quantity, cost, and location is managed from one system. When a change happens, it flows automatically across all listings and sales channels.

This centralization prevents fragmentation. It eliminates the risk of one platform showing outdated quantities. It allows sellers to see their entire operation in real time.

Without this foundation, scaling becomes unstable.

Standardized SKU Systems Create Order Out of Chaos

One of the most overlooked aspects of inventory control is SKU structure.

Many sellers create SKUs randomly. They mix numbers, letters, and product names without a plan. Over time, this becomes unmanageable.

Top sellers design SKUs that communicate information instantly. A good SKU tells you the category, brand, model, variation, and sometimes even the sourcing batch. When a picker scans an item, they immediately know what they are handling.

This consistency reduces mistakes. It speeds up training. It improves software performance. It allows automation to work properly.

Strong SKUs are invisible to buyers but essential to sellers.

Barcode and Scanner Systems Replace Human Memory

Once your inventory reaches a few thousand units, memory and visual checking are no longer reliable. Human error becomes unavoidable.

Professional sellers solve this with barcode systems. Every product is labeled. Every shelf is identified. Every movement is scanned.

When inventory arrives, it is scanned into the system. When orders are picked, they are scanned again. When items are packed, they are scanned once more. Returns are scanned at intake.

This creates a digital trail for every item. If something goes missing, sellers can trace exactly where the breakdown occurred.

At scale, scanners are not optional. They are survival tools.

Managing Multiple Warehouses and Storage Locations

Many large eBay businesses operate across several locations. Some use multiple warehouses. Others combine home storage, commercial units, and third-party fulfillment. Without proper systems, this becomes a logistical nightmare.

Professional sellers use location mapping inside their inventory software. Each SKU is assigned to a specific warehouse, aisle, shelf, and bin. Staff never guess where items are stored. They follow digital directions.

When inventory moves between locations, systems update automatically. When one warehouse runs low, orders are routed to another. When stock is unavailable, listings adjust.

This level of control prevents shipping delays and overselling.

Real-Time Stock Sync Protects Seller Metrics

Many eBay power sellers operate on more than one sales platform. They sell on eBay, their own website, and other marketplaces. Without real-time syncing, double-selling becomes inevitable.

Top sellers use systems that instantly update quantities across all channels when an item sells. This ensures that no platform displays incorrect availability.

Real-time syncing protects seller performance metrics and customer trust. It also eliminates manual updates that waste time and introduce errors.

Safety Buffers Protect Against System Failures

Elite sellers never list their full physical inventory. They build safety buffers into their systems.

This means they intentionally list slightly fewer units than they actually have. These buffers protect against damaged items, miscounts, returns in transit, and unexpected losses.

High-risk products receive larger buffers. Stable items receive smaller ones. These adjustments are based on historical data, not guesswork.

Buffers are silent profit protectors.

Receiving and Intake Is Where Accuracy Begins

Most inventory problems originate during receiving.

When new products arrive, professional sellers follow strict intake procedures. Every shipment is counted, inspected, scanned, photographed, and entered into the system immediately. Locations are assigned before items ever reach storage.

Nothing is shelved without being logged. Nothing is listed without verification.

This prevents phantom inventory and future disputes.

Continuous Cycle Counting Keeps Data Reliable

Rather than doing massive annual inventory counts, high-volume sellers use cycle counting.

Small portions of inventory are counted daily or weekly. Categories rotate on a schedule. Discrepancies are corrected immediately.

This keeps systems accurate year-round. It also reveals patterns, such as recurring errors or theft risks.

Cycle counting turns inventory accuracy into a daily habit instead of a yearly crisis.

Returns Are Managed as a Separate Operation

Returns can destroy inventory accuracy if handled poorly.

Professional sellers treat returns as their own workflow. Returned items are inspected, tested, cleaned, relabeled, and re-entered into inventory only after approval. Damaged items are removed immediately.

Nothing is restocked based on assumptions.

This protects listing accuracy and prevents defective products from circulating.

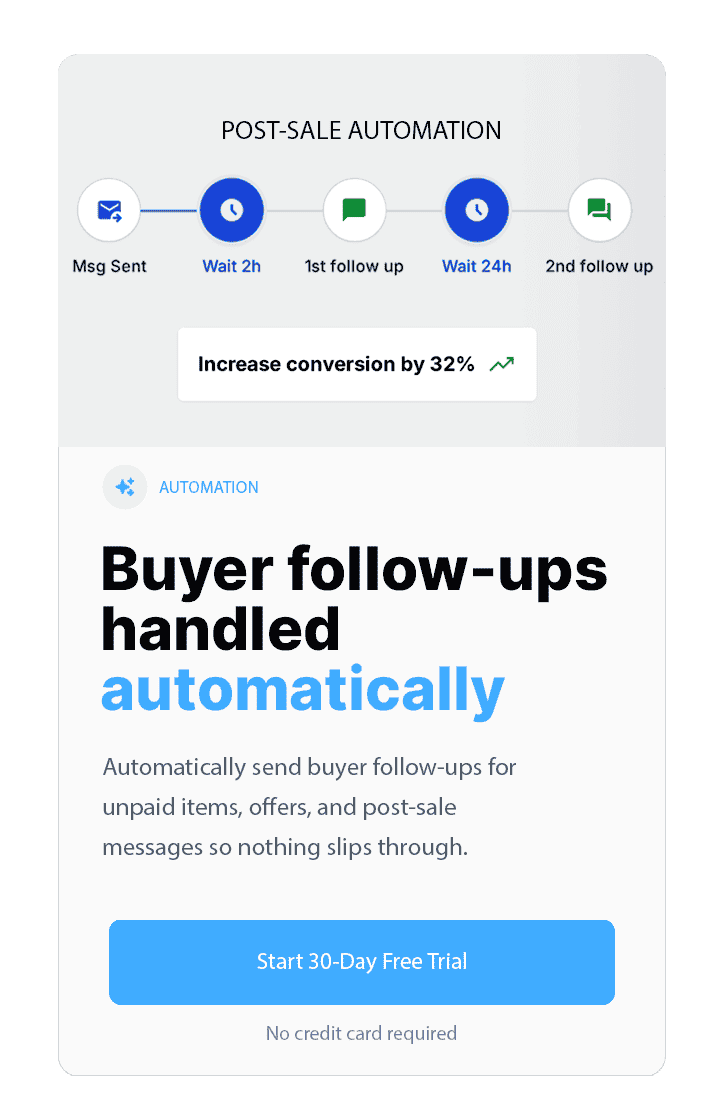

Automation Keeps Listings and Inventory Aligned

Inventory systems perform best when paired with listing optimization tools.

Platforms like MyListerHub help sellers maintain accurate catalogs by identifying stale listings, detecting mismatches, refreshing underperforming products, and correcting inconsistencies.

When listings remain accurate, inventory remains reliable. When listings drift, inventory collapses.

Automation keeps everything synchronized.

Error Prevention Is Designed Into the System

Top sellers do not rely on employees “being careful.” They build systems that prevent mistakes.

Orders are double-scanned. Package weights are verified. Pick confirmations are required. Audit trails are maintained.

If something does not match expected data, the system stops the process automatically.

These safeguards save thousands of dollars every year.

Inventory Forecasting Turns Data Into Profit

Professional sellers use historical data to predict demand.

They analyze sales velocity, seasonality, supplier lead times, and market trends. This allows them to restock before shortages occur and avoid overbuying slow-moving products.

Forecasting stabilizes cash flow. It improves turnover. It reduces dead stock.

Inventory planning is profit planning.

Why Many Sellers Fail to Scale Inventory Systems

Even experienced sellers make critical mistakes. They delay automation. They rely on spreadsheets too long. They avoid scanners. They skip cycle counts. They ignore analytics.

Each shortcut creates hidden weaknesses.

At scale, those weaknesses become expensive.

Building a System That Scales With You

Successful sellers build inventory systems in stages.

They start with standardized SKUs and labeling. They centralize data. They introduce automation. They refine processes. They expand locations. They train staff consistently.

They never stop improving.

Scaling is a process, not an event.

by Omri Ross